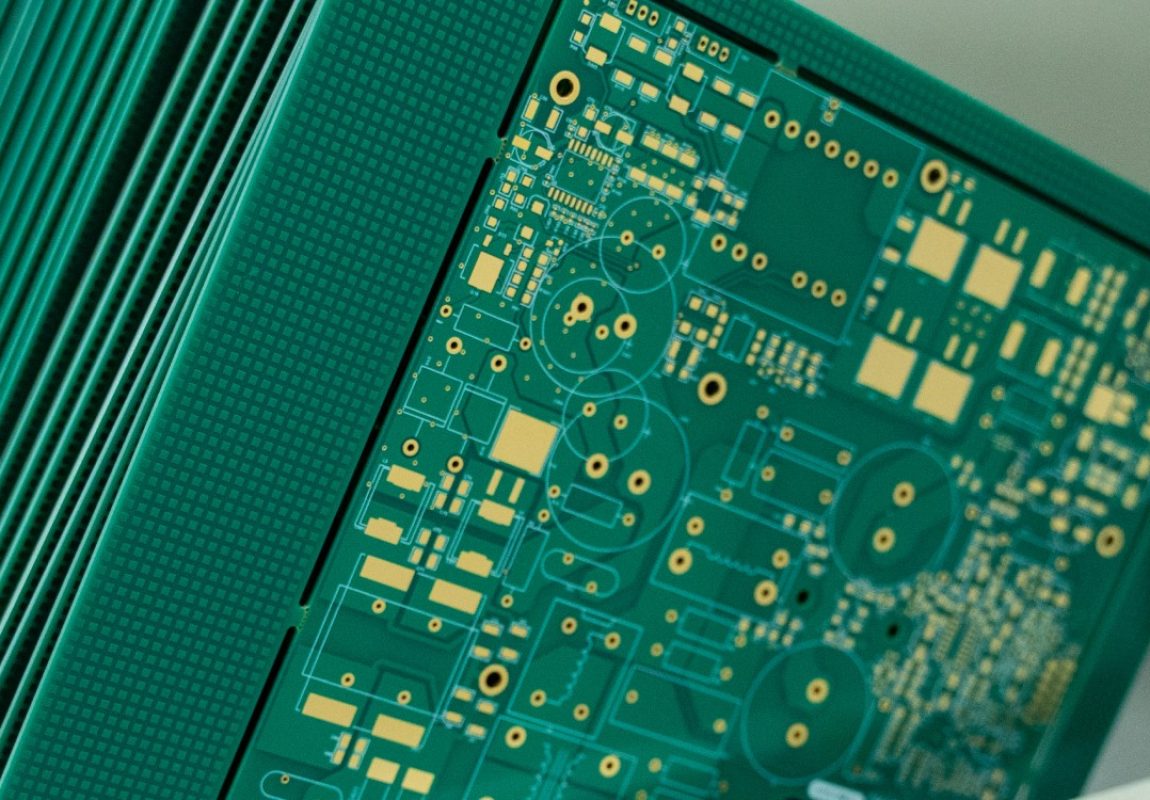

Wilson Process Systems operates one of the UK’s most advanced electronics manufacturing facilities, equipped to support high-volume and complex PCB assemblies. Our plant list reflects continual investment in precision machinery, automation, and inspection systems — ensuring repeatable quality, reliable throughput, and compliance with the highest industry standards.

Pick and Place Machine

Capacity: 25,000 component placements per hour

Pick and Place Machine

Capacity: 25,000 component placements per hour

Pick and Place Machine

Capacity: 65,500 component placements per hour

Pick and Place machines (x2 systems)

High speed chip placement platforms

Capacity: Up to 33,600 component placements per hour (each machine)

Reflow Ovens

Solder Paste Printer

Solder Paste Printer

Large Footprint Solder Paste Printer

Solder paste printer

Axial Insertion machine

Capacity: Up to 12,000 component insertions per hour

Radial insertion machine

Capacity: Up to 20,000 component insertions per hour

Radial insertion machine

Capacity: Up to 10,000 component insertions per hour

D.I.P insertion machine

Capacity: Up to 4,800 component insertions per hour

Pick and Place and Odd-form Machine

Capacity: 16,500 component placements per hour (full SM mode).

Selective Soldering System

High-speed, flexible, in-line, modular selective soldering system, comprising:

Wave soldering machine

Aqueous flux, micro-processor controlled, conveyorised wave soldering machine. Loaded with SN100C Tin, Copper, Nickel (lead-free) alloy.

Equipped with dual waves:

Wave soldering machine

Washer/drier system

Dual turbine, conveyorised, in-line, de-ionised, washer/drier system.

Cleans and dries the boards to the ultimate standard for this type of machine. The results of our ionograph analysis show levels of surface contamination well below those stipulated in MoD standards.

Fully automated, high speed, high accuracy Conformal Coating systems

In-Line, infrared cure ovens

Black polyurethane resin

Grey silicone, UL approved resin

Clear polyurethane resin

3D Automated Optical Inspection (AOI) system

2D Automated Optical Inspection (AOI) system

Environmental Test Chamber

Enables continuous temperature cycling between -70 and +180 degrees C and includes a patented psychrometric humidity measurement system

ATE Suites (3)

Automatic Test Equipment suites used for in-circuit testing and board set-up prior to despatch.

We can incorporate any customer or product-specific testing that may be required. This enables us to deliver zero-defect “ship-to-use” products for immediate use by the customer with no further goods- receiving inspection being required. And to offer a direct despatch service to customers, shipping tested, ready-to-use parts direct to the end user on our customer’s behalf.

Various bench equipment from Multi-Meters and Storage Scopes to Spectrum Analysers